About us

EON Energo -

EON Energo is an engineering services provider specialized in design, procurement, and equipment supply for oil processing and petrochemical facilities.

Established back in 2005, EON Energo LLP has now become an exemplar of growth and ambition concentrating on enhancement of our personnel’s qualifications and advancement of our technologies for the benefit of the Clients. We’re keeping in step with the time by applying best technologies and newest techniques. Our team’s relentlessly self-improving and demonstrating best working practices.

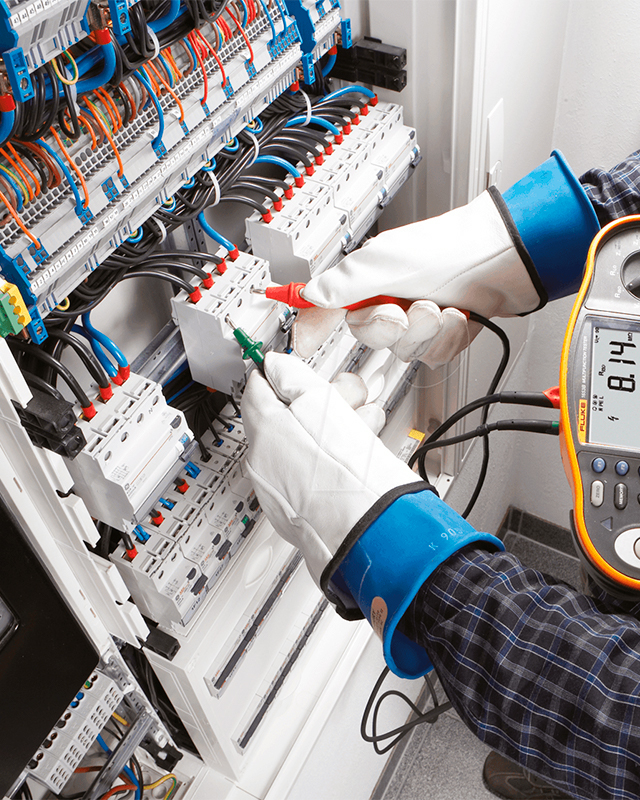

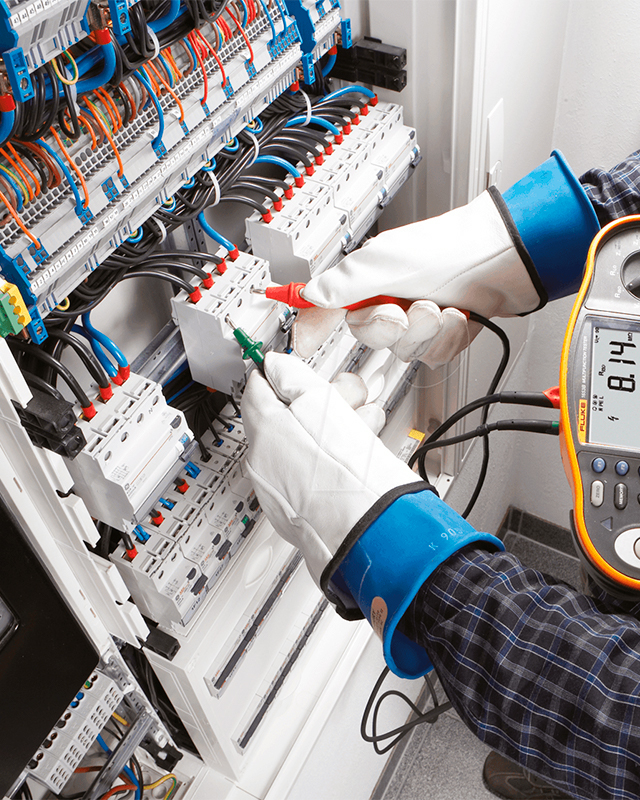

EON Energo’s been operating in construction business for over 15 years now, is offering an increasingly broad range of services and constantly expanding our project capabilities. We’re providing full scopes of construction, installation, and commissioning services.

EON Energo’s happy to offer a comprehensive range of construction and installation services suitable for any projects, no matter how challenging they are, including design, production of cost estimates, procurement of materials, and actual construction and installation on site during facility erection, maintenance or major turnarounds, and revamp.

Work Tools and Methods

To ensure excellent quality of a package of engineering services and project deliverables, we:

Procedures

Efficient, time-tested, proven project execution procedures

enables proper risk containment and prompt escalation of outstanding issues to a relevant leadership tier to ensure production of project deliverables per approved schedule

manages establishment of initial project teams’ as well as any membership changes in the course of the project

is implemented based on a project schedule by coordinating and approving the works between EON Energo and Client, as well as regular reviews of actual milestone deadlines.

covers requirements for project file naming and storage, submission of information to Client personnel, and a procedure for raising and addressing requests for information

stipulates a sequence of coordinated action at all stages of change management: initiation; documenting; review; approval or rejection; control of implementation

requires weekly progress meetings of project teams to review project performance and monthly meetings of the Managing Board to make key decisions and evaluate deliverables of each phase in particular and the project as a whole

Project Controls

Project management

- Participation in project team meetings to review work progress, incl. Managing Board meetings

- Assessment of project delivery efficiency

- Review of resource sharing efficiency

- Project plan performance control

- Project cost control

- Interface management and management of change reviews

Risk identification and analysis

- Review of interim and final risk analysis results from the prospective of accomplishment of project goals and objectives

- Identification of potential hazards, risks, and possible deviations that require more concentrated effort

- Quality control of risk management actions

Document management

- Control over scope completeness and quality of project deliverables

- Control over relevance and compliance of functional requirements and produced engineering solutions

- Tracking the project objectives and milestones completion dates

Delivery monitoring

- Review of design and engineering solutions for compliance with the approved project concept

- Review and evaluation of technical capacity for implementation of project solutions

- Support for implementation of changes to project systems

- Evaluation of data maturity

APPROACHES TO MAJOR PROJECT

RISK MANAGEMENT

Project-wide presence

EON Energo ensures proper control over project progress by placing its personnel at Client’s home office and regularly assigning engineers to various project sites (business trips to site, virtual meetings via conference calls)

Availability of large contractor / subcontractor workforces and client personnel

Development of unified project management procedures and control over performance; control over actual implementation of decisions approved per the Matrix of Approvals; review of a project orgchart and recommendations on its optimization

Short project durations with large numbers of contractor and client personnel involved

Efficient planning of project activities and excellent liaison management for all project stakeholders. Third-party evaluation of project resources sufficiency and quantities to accomplish project milestones as per approved schedule

Large number of end-to-end business decision makers resulting in potential decision-making conflicts

Implementation of escalation procedures to address disputes. Making sure that disputable issues are properly escalated; rejection of any decisions inhibiting progress of a project. Quality control to ensure the “Two-Man Rule” is being adhered to as applicable

PROJECT DESIGN DEPARTMENT (PDD)

PDD was first established back in 1981. Up to and throughout 2017, it used to be a division of POCR LLP’s organization. In 2018, pursuant to Non-Core Asset Outsourcing Strategy, PDD was integrated into EC KGNT LLP. In 2019, PDD team joined KING JSC. Most recently, in 2021, it was incorporated in EON Energo LLP’s organization.

Facility construction visualization

Engineering support during state expert review of project design and estimate documentation

Production of project design and estimate documentation for POCR LLP

Obtaining project approvals from state supervision and regulatory agencies

Engineering calculations

Project Design Department develops all Chapters of a Detailed Design Package, starting with receipt of a Design Assignment and up to approvals of Detailed Design, and conducts authorship supervision during construction.

Having joined EON Energo LLP, PDD was issued with a complete suite of proprietary software and State Licenses (permits) to Design.

3D PRINTING. ADDITIVE TECHNOLOGIES

These are techniques to fabricate items of various complexity by innovative production methods after the items have been designed with CAD/CAE/CAM systems.

3D printing includes stereolithography, fused deposition, laser sintering of metallic materials, direct laser deposition for metallic parts, gas dynamic cold spraying.

SLM

Selective Laser Melting

Selective Laser Melting

Selective melting of metallic powder with ytterbium laser per CAD model

SLS

Selective Laser Sintering

Selective Laser Sintering

Selective laser sintering of powdered material to fabricate a physical object per pre-designed CAD model

SLA

Laser Stereolithography

Laser Stereolithography

Laser stereolithography – layered curing of liquid material by laser

FDM

Fused Deposition Modeling

Fused Deposition Modeling

Fused deposition melting using plastic filament or pellets as feedstock

TURN-KEY PROJECTS

Our specialists are ready to offer to potential clients a complete range of turn-key project services, starting from front end design to executions and operations. While providing turn-key services, EON Energo acts as a general contractor overseeing the quality control of all project phases.

DESIGN

An engineering team produces project-specific diagrams, drawings, cost estimates, document deliverables and performs all necessary engineering design calculations

EXECUTION

EXECUTION Only highly qualified personnel are involved in construction of industrial facilities and fabrication of equipment

MAINTENANCE AND SERVICING

Highly qualified personnel handle facility and equipment maintenance, providing repair, installation, and revamp works

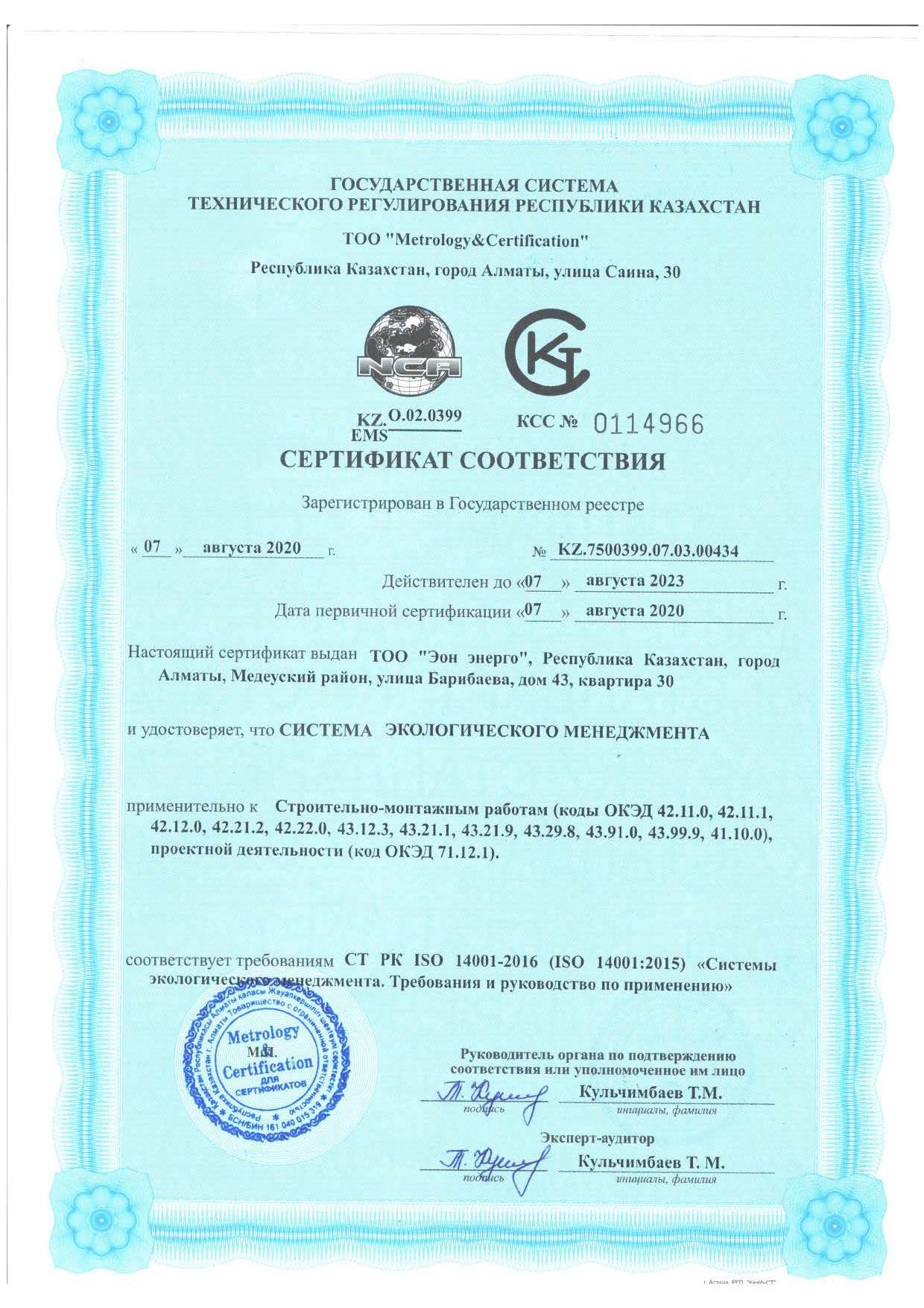

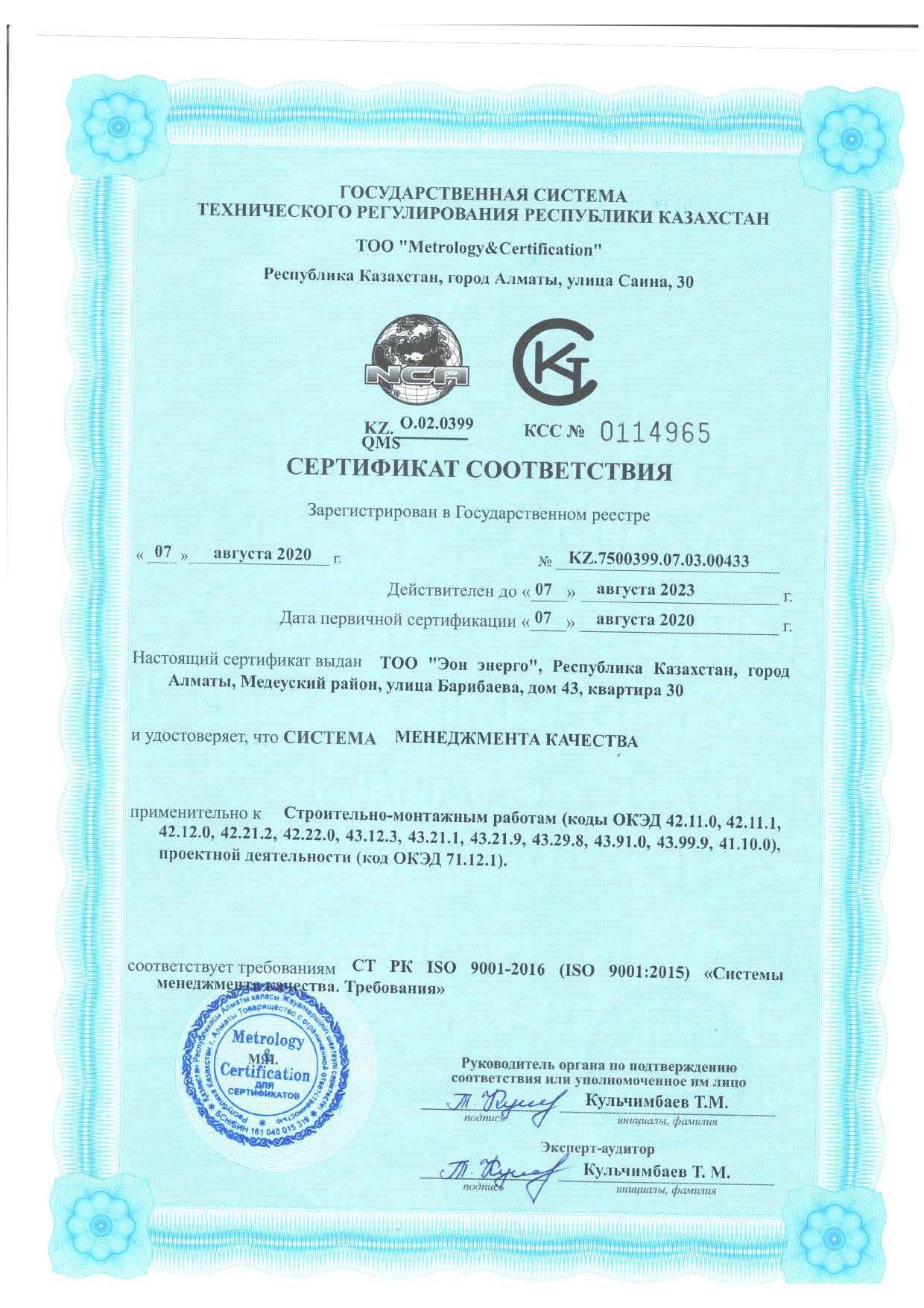

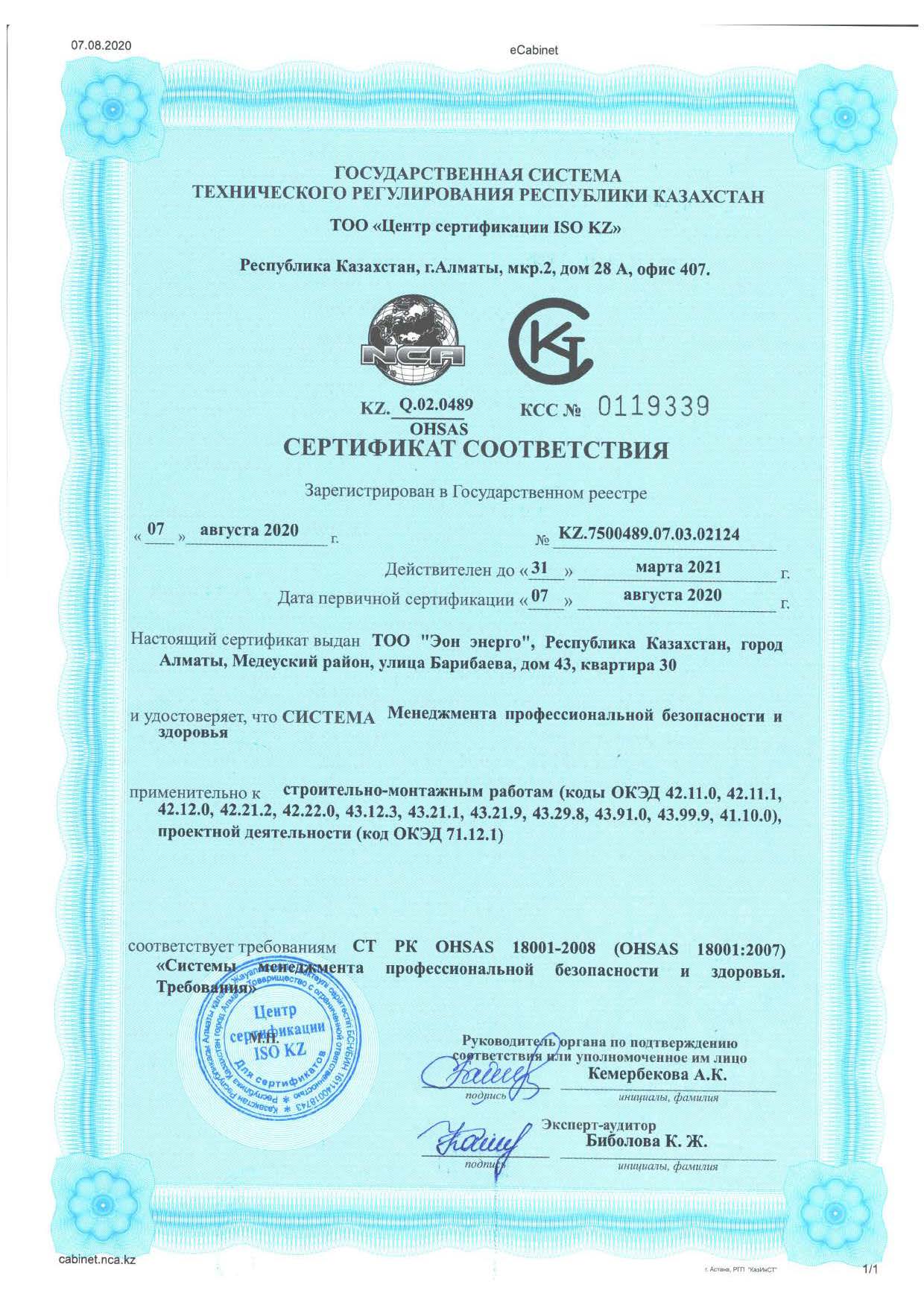

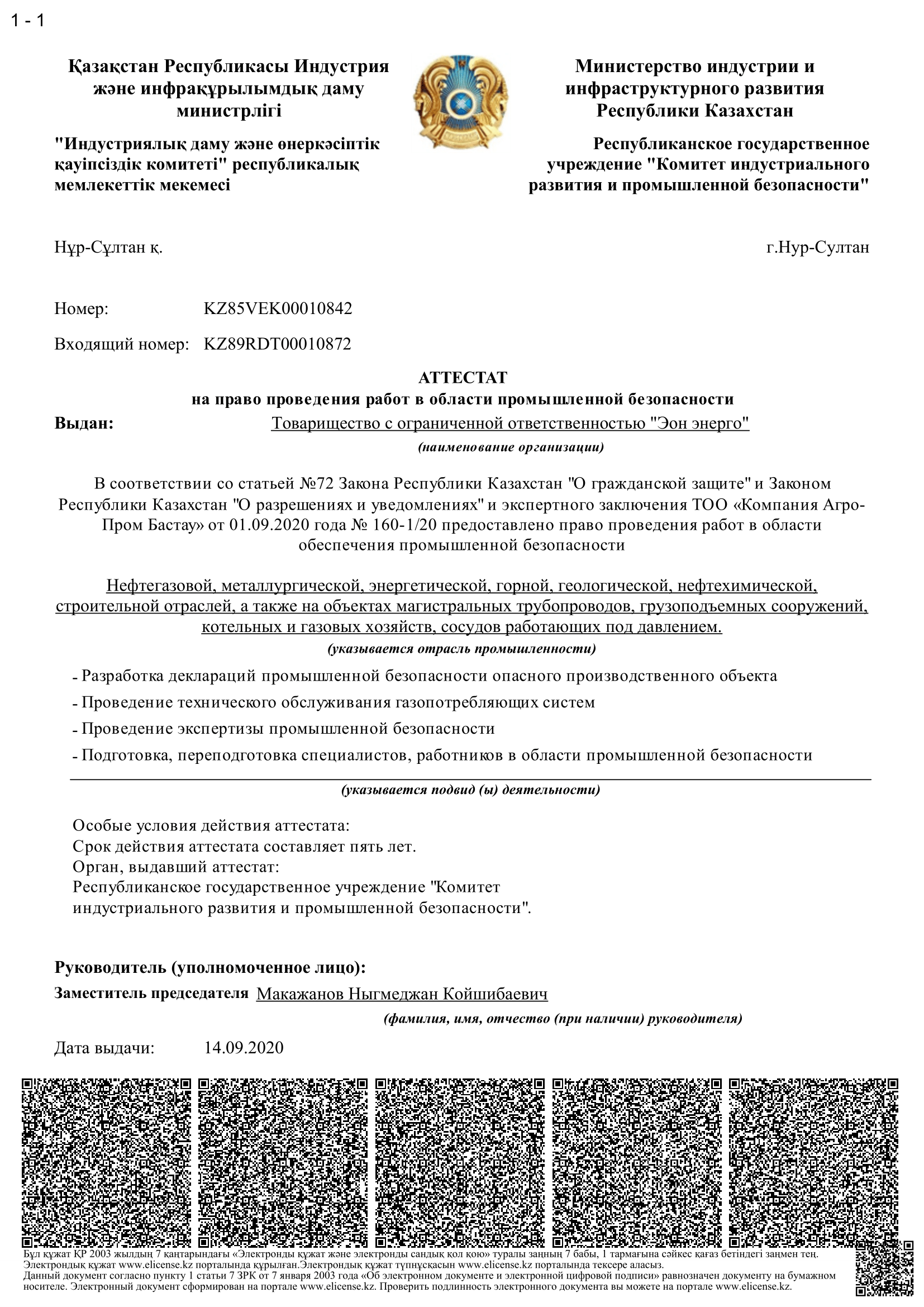

Certification